- Tel.: +86 512 5864 3048

- E-mail: admin@fillpackmachine.com

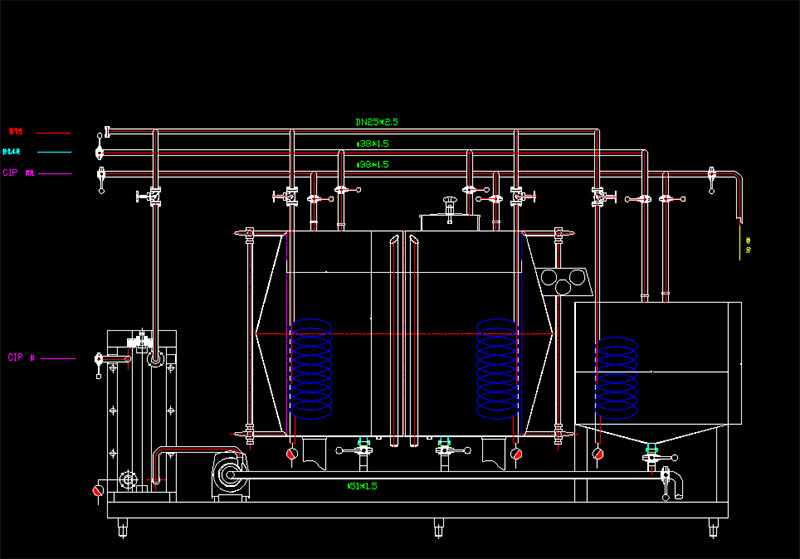

Title: Economical 2 in 1 combining CIP for small juice plant / diary plant

Key words: CIP, CIP cleaner, CIP machine

Model: CIP-500*2+1

Brand: FILL-PACK

Power: 2.2kw

Voltage: 380V 3PH 50HZ or customized

Driven force type: Electrical

Automation degree: automatic

Application: CIP cleaning for machine

Condition: New

PROPERTIES:

Capacity: 500L

Key material: SUS304

Fuction: CIP cleaning

Cleaning liquid: acid, alkali, hot water, clean water

Cleaning time: 15-25 mins per cycle

Heating way: electrical tube/ steam heating

Cleaning steps: 5

Origin: ZhangJiaGang, China

After sales service: Engineers avaliable to service overseas

Qualification: CE, ISO9001-2008

CIP is for easy equipments cleaning, usually suggested to divide into 5 steps of cleaning:

A, Water cleaning

When the filling material is finished, use water to clean immediately to eliminate residual material, at the same time it is more advantageous to the next step of liquid water cleaning. Water can be stop when the equipment flow of water out of clearing.

B, Alkali cleaning

The NaOH makes up to 2% concentration alkaline twist in the holding tank, heated to 80 ℃, then cycling about 30minutes. The alkali can dissolve protein, butterfat and make the fouling loose foam. If the scale is more serious, it can increase the concentration of the solution.

C, Water cleaning

Use water to flush about 15 minutes after removing the alkali.

D, Acid cleaning

Make the HNO3 into the concentration of 2% acidic detergent, then heat to 80℃, cycling about 30minutes.

E, Water cleaning

Use water to flush about 15 minutes after removing the acid, in case of the materials are polluted during reproduction.

CIP constructional design:

Parameters:

Material: SUS304 one layer

Acid tank: 500L

Alkali tank: 500L

Hot water tank: 500L

Thickness: 2mm

Dimension: 2800*1300*1800mm

Weight: 800kg

Sea shipping worthy packing will be applied;

15 working days leading time for delivery after order confirmed

1, Pre-quotation communication to know customers’ excat requirement and give proper suggested frame;

2, Quotation offer as in advance communications;

3, Quotation explanations given if necessary;

4, Plant design and bottle-cap-label searching & design if needed after offer confirmed;

5, Contract signing basing on all discussed;

6, Production as contract items;

7, Inspection and delivery done as contract standard;

8, Technician service overseas as contarct agreed;

9, Whole life after sales service for spare parts;

Copyright © ZhangJiaGang City FILL-PACK Machinery CO., LTD. All Rights Reserved

Technical Support: